The University of Utah College of Engineering is proud to announce the appointment of Professor Bruce Gale as the Merit Medical Systems, Inc. Endowed Professor of Engineering.

Professor Gale, who is also chair of the U’s Department of Mechanical Engineering, was honored during a ceremony May 13 at the University of Utah James L. Sorenson Molecular Biotechnology Building that included College of Engineering Dean Richard B. Brown and University of Utah President Taylor Randall.

“I was very surprised to receive this recognition. There are so many great professors here at the University of Utah College of Engineering,” said Gale. “I am grateful to Merit Medical Systems and Fred Lampropoulos for providing this Endowed Professorship. I am excited by the opportunities this will present for me and my team to engage in exciting new research projects.”

Bruce Gale

Professor Bruce Gale is chair of the Department of Mechanical Engineering where he has graduated 28 Ph.D. students and currently advises 10 Ph.D. students. He has published over 150 journal articles and 300 conference papers. He received a bachelor’s degree in mechanical engineering from Brigham Young University and a doctorate degree in bioengineering from the U. Gale arrived at the U as an assistant professor of mechanical engineering in 2001, was named professor in 2013, and became chair of the department in 2018. He also is director of the State of Utah Center of Excellence for Biomedical Microfluidics.

Professor Bruce Gale is chair of the Department of Mechanical Engineering where he has graduated 28 Ph.D. students and currently advises 10 Ph.D. students. He has published over 150 journal articles and 300 conference papers. He received a bachelor’s degree in mechanical engineering from Brigham Young University and a doctorate degree in bioengineering from the U. Gale arrived at the U as an assistant professor of mechanical engineering in 2001, was named professor in 2013, and became chair of the department in 2018. He also is director of the State of Utah Center of Excellence for Biomedical Microfluidics.

Professor Gale has started six companies and served as their head of engineering, including for Microsurgical Innovations, Espira, Advanced Conceptions, wFluidx and Carterra. He has 25 issued patents.

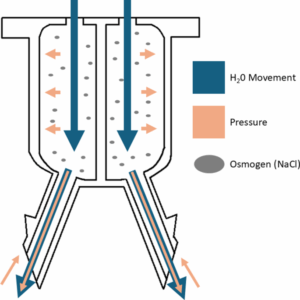

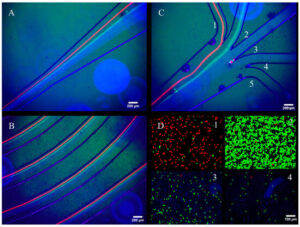

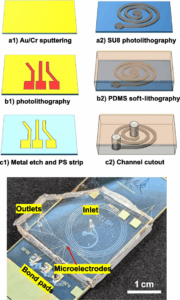

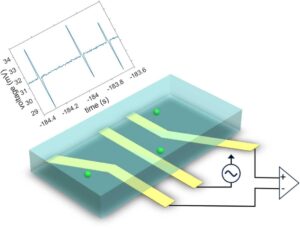

His research is centered on biomedical applications of microfluidics. He also has expertise in biosensors, microarrays, micropumps, and microscale medical devices.

The professor has a long list of college, university, and national academic achievements. He was elected Fellow of the National Academy of Inventors for 2021 and received the Fulbright Specialist Program award which enabled him to travel to the Rajalakshmi Engineering College in India where he helped develop a microfluidics research program. In May 2022 he was awarded the prestigious Governor’s Medal for Science and Technology from the Utah Governor’s Office of Economic Opportunity.

Merit Medical Systems, Inc.

Merit Medical is a leading manufacturer and marketer of proprietary disposable medical devices used in interventional, diagnostic, and therapeutic procedures, particularly in cardiology, radiology, oncology, critical care, and endoscopy. Merit has made it a priority to understand customers, innovate, and deliver life-changing products and services.

Merit’s founder, Fred Lampropoulos, has been in the medical device industry for more than 30 years. He currently serves as the company’s chairman and chief executive officer.

Lampropoulos holds more than 200 patents on devices used in the diagnostic and therapeutic treatment of cardiac, peripheral, gastrointestinal, and pulmonary conditions. He is also highly involved in his community and serves on many boards.

Lampropoulos is the recipient of numerous awards, including the Governor’s Medal for Science and Technology and CEO of the Year. He was inducted into the Utah Business Hall of Fame, the Utah Technology Hall of Fame and was recognized as the 2019 Giant in our City.

Professor Bruce Gale, Ph.D., Department of Mechanical Engineering Chair and Merit Medical Professor at University of Utah, uses microfluidics to solve problems. In the past he has developed tools for drug development, pathogen detection, fast PCR technologies, medical devices and more. Now he is turning that expertise toward automating the design of microfluidic devices to perform specific tests, assays, and more.

Professor Bruce Gale, Ph.D., Department of Mechanical Engineering Chair and Merit Medical Professor at University of Utah, uses microfluidics to solve problems. In the past he has developed tools for drug development, pathogen detection, fast PCR technologies, medical devices and more. Now he is turning that expertise toward automating the design of microfluidic devices to perform specific tests, assays, and more. Professor Bruce Gale is chair of the Department of Mechanical Engineering where he has graduated 28 Ph.D. students and currently advises 10 Ph.D. students. He has published over 150 journal articles and 300 conference papers. He received a bachelor’s degree in mechanical engineering from Brigham Young University and a doctorate degree in bioengineering from the U. Gale arrived at the U as an assistant professor of mechanical engineering in 2001, was named professor in 2013, and became chair of the department in 2018. He also is director of the State of Utah Center of Excellence for Biomedical Microfluidics.

Professor Bruce Gale is chair of the Department of Mechanical Engineering where he has graduated 28 Ph.D. students and currently advises 10 Ph.D. students. He has published over 150 journal articles and 300 conference papers. He received a bachelor’s degree in mechanical engineering from Brigham Young University and a doctorate degree in bioengineering from the U. Gale arrived at the U as an assistant professor of mechanical engineering in 2001, was named professor in 2013, and became chair of the department in 2018. He also is director of the State of Utah Center of Excellence for Biomedical Microfluidics.