Mechanical Engineering associate professor Bart Raeymaekers and professor Bruce Gale receive $16 million in funding over the next five years from both federal and state governments as well as local industry to develop a new center to help local manufacturing businesses succeed.

Mechanical Engineering associate professor Bart Raeymaekers and professor Bruce Gale receive $16 million in funding over the next five years from both federal and state governments as well as local industry to develop a new center to help local manufacturing businesses succeed.

One of the hot-button issues this presidential election is about companies outsourcing work overseas and figuring out how to keep manufacturing jobs here in America. To help convince these businesses they can perform better in their own backyard, two University of Utah mechanical engineering professors are establishing a center to show local manufacturing companies how they can spur innovation and utilize the latest in technology.

The new University of Utah Manufacturing Extension Partnership (MEP) Center will deliver services for small and medium-sized manufacturing companies by providing expertise in advanced manufacturing technology, innovation, worker education, operational excellence, and on how to connect companies with investor opportunities.

“The goal of the program is to provide these services so businesses can remain competitive against cheap overseas labor and to keep those manufacturing jobs here,” says University of Utah mechanical engineering associate professor Bart Raeymaekers, who along with mechanical engineering professor Bruce Gale are creators of the center and recipients of the grant.

The center, in partnership with other entities and organizations throughout the state, will help local businesses:

- Use data to identify products and markets that are growing and provide resources for the prototyping of new products.

- Implement advanced manufacturing equipment and technology.

- Develop and educate their workforce to use these new technologies.

- Connect with investors and secure government grants to increase funding.

- Learn how to make their operations more efficient to maximize profits.

The University of Utah’s MEP Center will receive funding from the U.S. commerce department’s National Institute of Standards and Technology (NIST) and the Utah Governor’s Office of Economic Development (GOED). All told, the center will receive $16 million in funding over the next five years from both federal and state governments as well as local industry. Utah is one of 11 states and Puerto Rico to have received NIST funding this month for local MEP centers.

The Utah center, which will be under the U’s College of Engineering, will begin operations Oct. 1 and be headquartered on the U campus. It will employ at least a dozen permanent employees, consultants and industry professionals. It will open satellite offices in Cache and Utah counties as well as have consultants in eastern Utah and Cedar City.

There are more than 3,300 manufacturing companies in Utah, ranging in areas from chemical products and computer and electronic products to metals, aerospace equipment and food products, according to publicly available data.

Utah Business follow-up story

received his undergraduate degree in Mechanical Engineering from Brigham Young University in 1995 and his PhD in Bioengineering from the University of Utah in 2000. He was an assistant professor of Biomedical Engineering at Louisiana Tech University before returning to the University of Utah in 2001 where he is now a professor of Mechanical Engineering. He is currently Director of both the Utah State Center of Excellence for Biomedical Microfluidics and the College of Engineering Nanofabrication Facility. He is also Chief Science Officer at Wasatch Microfluidics, a multiplexed instrument development company focused on protein characterization in the pharmaceutical industry that was spun out of his lab in 2005. He has three additional recent startups where he serves as chief scientist: Espira, which focuses on pathogen detection and exosome separations; Nanonc, which focuses on reproductive medicine applications of microfluidics; and Microsurgical Innovations, which focuses on miniature medical devices. He has been working in the area of microfluidics, nanotechnology, medical devices, and micro-total-analysis systems (-TAS) for the past 18 years. His primary interests include lab-on- a chip devices that require a variety of microfluidic components for the completion of complex and challenging medical and biological assays. Specifically, he is working to develop a microfluidic toolbox for the rapid design, simulation, and fabrication of devices with medical and biological applications. The ultimate goal is to develop platforms for personalized medicine, which should allow medical treatments to be customized to the needs of individual patients. He also has expertise in nanoscale patterning of proteins and sensors, nanoparticle characterization, miniature medical devices, and nanofabrication techniques.

received his undergraduate degree in Mechanical Engineering from Brigham Young University in 1995 and his PhD in Bioengineering from the University of Utah in 2000. He was an assistant professor of Biomedical Engineering at Louisiana Tech University before returning to the University of Utah in 2001 where he is now a professor of Mechanical Engineering. He is currently Director of both the Utah State Center of Excellence for Biomedical Microfluidics and the College of Engineering Nanofabrication Facility. He is also Chief Science Officer at Wasatch Microfluidics, a multiplexed instrument development company focused on protein characterization in the pharmaceutical industry that was spun out of his lab in 2005. He has three additional recent startups where he serves as chief scientist: Espira, which focuses on pathogen detection and exosome separations; Nanonc, which focuses on reproductive medicine applications of microfluidics; and Microsurgical Innovations, which focuses on miniature medical devices. He has been working in the area of microfluidics, nanotechnology, medical devices, and micro-total-analysis systems (-TAS) for the past 18 years. His primary interests include lab-on- a chip devices that require a variety of microfluidic components for the completion of complex and challenging medical and biological assays. Specifically, he is working to develop a microfluidic toolbox for the rapid design, simulation, and fabrication of devices with medical and biological applications. The ultimate goal is to develop platforms for personalized medicine, which should allow medical treatments to be customized to the needs of individual patients. He also has expertise in nanoscale patterning of proteins and sensors, nanoparticle characterization, miniature medical devices, and nanofabrication techniques. Research Assistant Professor

Research Assistant Professor

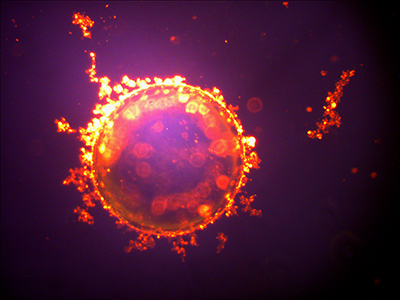

chromosome purification. Such a device would enable the development of an improved intercellular chromosome transfer process.

chromosome purification. Such a device would enable the development of an improved intercellular chromosome transfer process.